Low energy consumption green technology for aromatics

The low-energy-consumption green aromatic hydrocarbon technology suite was independently developed by Zhejiang Dongjiang Green Petrochemical Technology Innovation Center Co., Ltd. Currently, this technology mainly includes: low-temperature heat utilization and process condensate recovery technology for aromatic hydrocarbon units, and combined technology for liquid-phase isomerization and deethylation isomerization units.

Classification:

Iconic Results

Key words:

Low energy consumption green technology for aromatics

Graphic Details

Results Overview

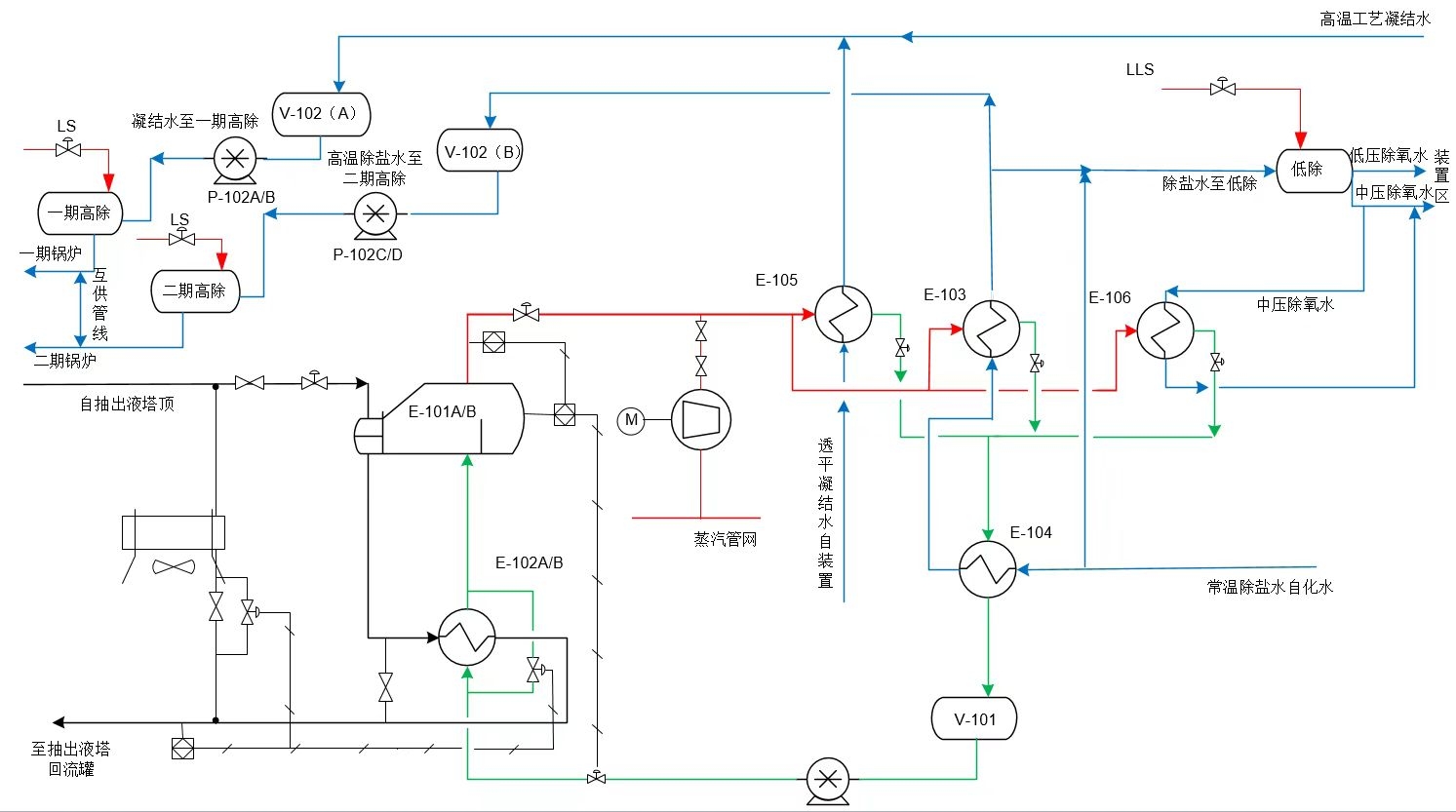

The low-energy consumption aromatic hydrocarbon green technology suite was independently developed by Zhejiang Dongjiang Green Petrochemical Technology Innovation Center Co., Ltd. Currently, this technology mainly includes: low-temperature heat utilization and process condensate recovery technology for aromatic hydrocarbon units, and a combination technology of liquid-phase isomerization and de-ethyl isomerization units. The process technology flow is as follows:

- Low-temperature Heat Utilization and Process Condensate Recovery Technology for Aromatic Hydrocarbon Units

- Combination Technology of Liquid-Phase Isomerization and De-ethyl Isomerization Units

Main Technological Characteristics

- Recovery of low-temperature heat from aromatic hydrocarbon units. By producing ultra-low pressure steam and then upgrading it through a compressor, the problem of insufficient cold sources is solved. For example: 0.1 MPa is increased to 0.5 MPa, or 0.5 MPa is increased to 2.5 MPa. 2.5 MPa superheated steam can replace the medium-pressure steam of 3.5 MPa temperature reduction and pressure reduction in the unit.

- For long-distance transportation of low-temperature heat from the unit, demineralized water can be used as the heat transfer medium to solve the problem of long-distance steam transportation.

- A large amount of high-temperature, clean process condensate exists in aromatic hydrocarbon units. Directly using it in a high-pressure deaerator reduces the cost of process condensate treatment and, by saving high-temperature steam, lowers production costs.

- The combined liquid-phase isomerization and de-ethyl isomerization unit can increase the xylene yield to over 99.3%, while reducing unit energy consumption by more than 5%.

Application Achievements

Zhongjin Petrochemical Co., Ltd. intelligent thermal island waste heat recovery unit (2025)

Other related

undefined

Contact Us

-

Address: 20th Floor, Building 5, Zone A, R&D Park,

High-tech Zone, Ningbo City, Zhejiang Province

Postcode: 315100

E-mail: chuangxinzhongxin@zjdjgpt.com

Telephone: +86-574-86661203

Zhejiang Innovation Center

of Green Petrochemical Technology

All rights reserved © 2024 Zhejiang Dongjiang Green Petrochemical Technology Innovation Centre Co., Ltd.

SEO | Powered by www.300.cn